Ball Valve Torque Value and Top Mounting Flange Dimensions

Ball valve torque values for floating and trunnion mounted ball valves, sizes from 1/2" to 24", Class 150–2500, top mounting flange dimensions are as per ISO 5211.

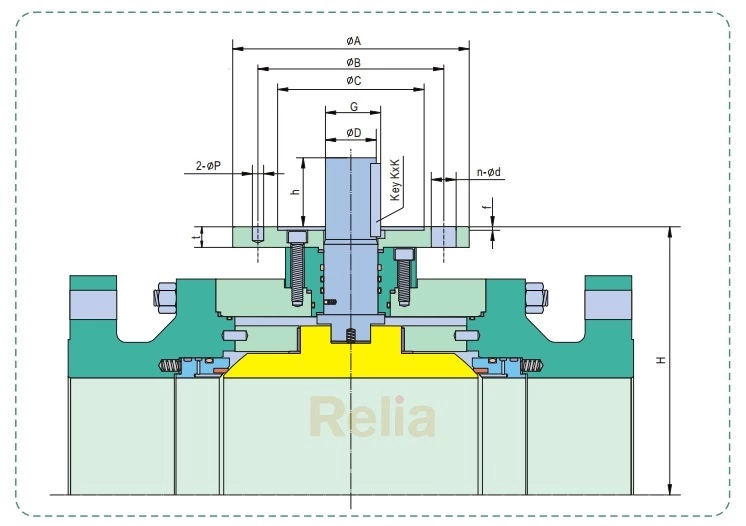

Trunnion Ball Valve Torque Value and Top Mounting Flange Dimensions

| Size inch |

Class | Torque N.m |

Flange Dimensions (mm) |

ISO 5211 Flange No. |

Key Size KxK mm |

G mm |

D mm |

h mm |

H mm |

||||||

| A | B | C | f | t | n-d | P | |||||||||

| 1-1/2 | 150 | 42 | 90 | 70 | 55 | 3 | 12 | 4-9 | 6 | F07 | 6x6 | 25 | 22 | 25 | 100 |

| 300 | 66 | 90 | 70 | 55 | 3 | 12 | 4-9 | 6 | F07 | 6x6 | 25 | 22 | 25 | 100 | |

| 600 | 102 | 90 | 70 | 55 | 3 | 12 | 4-9 | 6 | F07 | 6x6 | 25 | 22 | 25 | 100 | |

| 900 | 142 | 90 | 70 | 55 | 3 | 12 | 4-9 | 6 | F07 | 6x6 | 25 | 22 | 25 | 100 | |

| 1500 | 241 | 90 | 70 | 55 | 3 | 12 | 4-9 | 6 | F07 | 6x6 | 25 | 22 | 25 | 100 | |

| 2500 | 423 | 125 | 102 | 70 | 3 | 15 | 4-11 | 8 | F10 | 8x8 | 32 | 28 | 30 | 115 | |

| 2 | 150 | 76 | 90 | 70 | 55 | 3 | 12 | 4-9 | 6 | F07 | 6x6 | 25 | 22 | 25 | 103 |

| 300 | 91 | 90 | 70 | 55 | 3 | 12 | 4-9 | 6 | F07 | 6x6 | 25 | 22 | 25 | 103 | |

| 600 | 143 | 90 | 70 | 55 | 3 | 12 | 4-9 | 6 | F07 | 6x6 | 25 | 22 | 25 | 103 | |

| 900 | 231 | 125 | 102 | 70 | 3 | 15 | 4-11 | 8 | F10 | 8x8 | 32 | 28 | 30 | 117 | |

| 1500 | 349 | 125 | 102 | 70 | 3 | 15 | 4-11 | 8 | F10 | 8x8 | 32 | 28 | 30 | 117 | |

| 2500 | 798 | 150 | 125 | 85 | 3 | 18 | 4-13 | 10 | F12 | 10x10 | 41 | 36 | 55 | 135 | |

| 3 | 150 | 121 | 125 | 102 | 70 | 3 | 15 | 4-11 | 8 | F10 | 8x8 | 32 | 28 | 30 | 130 |

| 300 | 159 | 125 | 102 | 70 | 3 | 15 | 4-11 | 8 | F10 | 8x8 | 32 | 28 | 30 | 130 | |

| 600 | 269 | 125 | 102 | 70 | 3 | 15 | 4-11 | 8 | F10 | 8x8 | 32 | 28 | 30 | 132 | |

| 900 | 524 | 150 | 125 | 85 | 3 | 18 | 4-13 | 10 | F12 | 10x10 | 41 | 36 | 55 | 142 | |

| 1500 | 887 | 150 | 125 | 85 | 3 | 18 | 4-13 | 10 | F12 | 10x10 | 41 | 36 | 55 | 147 | |

| 2500 | 1583 | 175 | 140 | 100 | 4 | 20 | 4-18 | 10 | F14 | 12x12 | 51 | 45 | 65 | 165 | |

| 4 | 150 | 179 | 125 | 102 | 70 | 3 | 15 | 4-11 | 8 | F10 | 8x8 | 32 | 28 | 30 | 150 |

| 300 | 355 | 125 | 102 | 70 | 3 | 15 | 4-11 | 8 | F10 | 8x8 | 32 | 28 | 30 | 150 | |

| 600 | 670 | 150 | 125 | 85 | 3 | 18 | 4-13 | 10 | F12 | 10x10 | 41 | 36 | 55 | 160 | |

| 900 | 875 | 175 | 140 | 100 | 4 | 20 | 4-18 | 10 | F14 | 12x12 | 51 | 45 | 65 | 172 | |

| 1500 | 1351 | 210 | 165 | 130 | 5 | 22 | 4-22 | 12 | F16 | 14x14 | 57 | 50 | 75 | 185 | |

| 2500 | 2111 | 210 | 165 | 130 | 5 | 22 | 4-22 | 12 | F16 | 14x14 | 62 | 55 | 80 | 205 | |

| 6 | 150 | 631 | 150 | 125 | 85 | 3 | 18 | 4-13 | 10 | F12 | 10x10 | 41 | 36 | 55 | 186 |

| 300 | 854 | 150 | 125 | 85 | 3 | 18 | 4-13 | 10 | F12 | 10x10 | 41 | 36 | 55 | 186 | |

| 600 | 1609 | 175 | 140 | 100 | 4 | 20 | 4-18 | 10 | F14 | 12x12 | 51 | 45 | 65 | 208 | |

| 900 | 1927 | 210 | 165 | 130 | 5 | 22 | 4-22 | 12 | F16 | 14x14 | 62 | 55 | 80 | 215 | |

| 1500 | 3512 | 210 | 165 | 130 | 5 | 24 | 4-22 | 14 | F16 | 16x16 | 68 | 60 | 90 | 255 | |

| 2500 | 5454 | 300 | 254 | 200 | 5 | 26 | 8-18 | 16 | F25 | 16x16 | 73 | 65 | 95 | 305 | |

| 8 | 150 | 987 | 210 | 165 | 130 | 5 | 20 | 4-22 | 10 | F16 | 12x12 | 51 | 45 | 60 | 233 |

| 300 | 1562 | 210 | 165 | 130 | 5 | 20 | 4-22 | 10 | F16 | 12x12 | 51 | 45 | 60 | 233 | |

| 600 | 2501 | 210 | 165 | 130 | 5 | 22 | 4-22 | 12 | F16 | 14x14 | 62 | 55 | 80 | 250 | |

| 900 | 4012 | 210 | 165 | 130 | 5 | 22 | 4-22 | 14 | F16 | 16x16 | 68 | 60 | 90 | 260 | |

| 1500 | 6513 | 300 | 254 | 200 | 5 | 25 | 8-18 | 16 | F25 | 18x18 | 79 | 70 | 105 | 280 | |

| 2500 | 8495 | 300 | 254 | 200 | 5 | 28 | 8-18 | 16 | F25 | 18x18 | 84 | 75 | 110 | 360 | |

| 10 | 150 | 1321 | 210 | 165 | 130 | 5 | 22 | 4-22 | 12 | F16 | 14x14 | 62 | 55 | 80 | 280 |

| 300 | 2304 | 210 | 165 | 130 | 5 | 22 | 4-22 | 12 | F16 | 14x14 | 62 | 55 | 80 | 280 | |

| 600 | 3450 | 210 | 165 | 130 | 5 | 24 | 4-22 | 14 | F16 | 16x16 | 68 | 60 | 90 | 290 | |

| 900 | 5017 | 300 | 254 | 200 | 5 | 25 | 8-18 | 16 | F25 | 18x18 | 79 | 70 | 105 | 305 | |

| 1500 | 7996 | 300 | 254 | 200 | 5 | 28 | 8-18 | 16 | F25 | 18x18 | 84 | 75 | 110 | 345 | |

| 2500 | 13148 | 300 | 254 | 200 | 5 | 28 | 8-18 | 16 | F25 | 20x20 | 95 | 85 | 125 | 390 | |

| 12 | 150 | 1650 | 210 | 165 | 130 | 5 | 24 | 4-22 | 14 | F16 | 16x16 | 68 | 60 | 90 | 315 |

| 300 | 3041 | 210 | 165 | 130 | 5 | 24 | 4-22 | 14 | F16 | 16x16 | 68 | 60 | 90 | 315 | |

| 600 | 4507 | 300 | 254 | 200 | 5 | 25 | 8-18 | 16 | F25 | 18x18 | 79 | 70 | 105 | 345 | |

| 900 | 6512 | 300 | 254 | 200 | 5 | 28 | 8-18 | 16 | F25 | 18x18 | 84 | 75 | 110 | 360 | |

| 1500 | 10078 | 300 | 254 | 200 | 5 | 28 | 8-18 | 16 | F25 | 20x20 | 95 | 85 | 125 | 405 | |

| 2500 | 18007 | 300 | 254 | 200 | 5 | 30 | 8-18 | 16 | F25 | 24x24 | 107 | 95 | 140 | 465 | |

| 14 | 150 | 2415 | 300 | 254 | 200 | 5 | 26 | 8-18 | 16 | F25 | 16x16 | 73 | 65 | 95 | 353 |

| 300 | 4019 | 300 | 254 | 200 | 5 | 26 | 8-18 | 16 | F25 | 16x16 | 73 | 65 | 95 | 353 | |

| 600 | 6578 | 300 | 254 | 200 | 5 | 28 | 8-18 | 16 | F25 | 18x18 | 84 | 75 | 110 | 370 | |

| 900 | 9489 | 300 | 254 | 200 | 5 | 28 | 8-18 | 16 | F25 | 20x20 | 95 | 85 | 125 | 390 | |

| 1500 | 14860 | 300 | 254 | 200 | 5 | 30 | 8-18 | 16 | F25 | 24x24 | 107 | 95 | 140 | 435 | |

| 16 | 150 | 3314 | 300 | 254 | 200 | 5 | 28 | 8-18 | 16 | F25 | 18x18 | 84 | 75 | 110 | 393 |

| 300 | 5350 | 300 | 254 | 200 | 5 | 28 | 8-18 | 16 | F25 | 18x18 | 84 | 75 | 110 | 400 | |

| 600 | 9025 | 300 | 254 | 200 | 5 | 28 | 8-18 | 16 | F25 | 20x20 | 95 | 85 | 125 | 420 | |

| 900 | 12877 | 300 | 254 | 200 | 5 | 30 | 8-18 | 16 | F25 | 24x24 | 107 | 95 | 140 | 440 | |

| 1500 | 21857 | 350 | 298 | 230 | 5 | 32 | 8-22 | 20 | F30 | 28x28 | 119 | 105 | 165 | 485 | |

| 18 | 150 | 5148 | 300 | 254 | 200 | 5 | 28 | 8-18 | 16 | F25 | 18x18 | 84 | 75 | 110 | 435 |

| 300 | 8375 | 300 | 254 | 200 | 5 | 28 | 8-18 | 16 | F25 | 20x20 | 95 | 85 | 125 | 440 | |

| 600 | 13493 | 300 | 254 | 200 | 5 | 30 | 8-18 | 16 | F25 | 24x24 | 107 | 95 | 140 | 462 | |

| 900 | 18975 | 350 | 298 | 230 | 5 | 32 | 8-22 | 20 | F30 | 28x28 | 119 | 105 | 165 | 500 | |

| 1500 | 29032 | 350 | 298 | 230 | 5 | 38 | 8-22 | 20 | F30 | 32x32 | 136 | 120 | 180 | 545 | |

| 20 | 150 | 6425 | 300 | 254 | 200 | 5 | 30 | 8-18 | 16 | F25 | 20x20 | 90 | 80 | 120 | 485 |

| 300 | 10987 | 300 | 254 | 200 | 5 | 30 | 8-18 | 16 | F25 | 24x24 | 107 | 95 | 140 | 490 | |

| 600 | 18502 | 350 | 298 | 230 | 5 | 32 | 8-22 | 20 | F30 | 28x28 | 119 | 105 | 165 | 515 | |

| 900 | 26048 | 350 | 298 | 230 | 5 | 38 | 8-22 | 20 | F30 | 32x32 | 136 | 120 | 180 | 530 | |

| 1500 | 40907 | 415 | 356 | 260 | 5 | 42 | 8-33 | 28 | F35 | 36x36 | 158 | 140 | 210 | 580 | |

| 24 | 150 | 12379 | 300 | 254 | 200 | 5 | 32 | 8-18 | 16 | F25 | 24x24 | 102 | 90 | 135 | 562 |

| 300 | 19384 | 350 | 298 | 230 | 5 | 32 | 8-22 | 20 | F30 | 28x28 | 124 | 110 | 165 | 570 | |

| 600 | 29546 | 350 | 298 | 230 | 5 | 38 | 8-22 | 20 | F30 | 32x32 | 136 | 120 | 180 | 610 | |

| 900 | 42379 | 415 | 356 | 260 | 5 | 42 | 8-33 | 28 | F35 | 36x36 | 158 | 140 | 210 | 630 | |

| 1500 | 65223 | 475 | 406 | 300 | 8 | 48 | 8-39 | 28 | F40 | 40x40 | 180 | 160 | 240 | 730 | |

Notes:

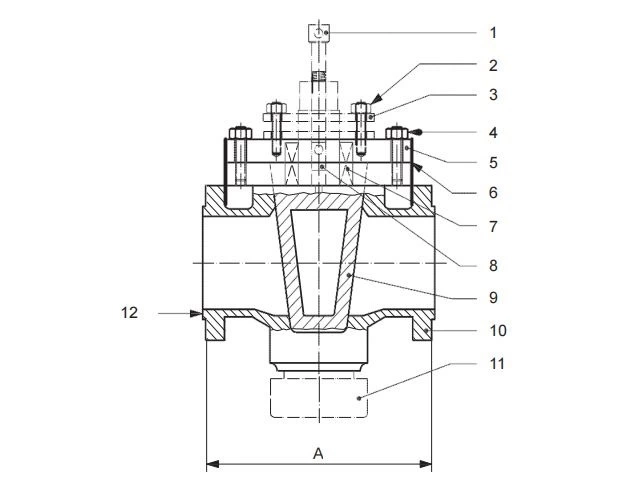

1. The above table is for side entry trunnion mounted ball valves, which are with ISO 5211 mounting flange andadaptablity for all types actuators mounting.

2. The torque is for valves with PTFE seat or Molon seat as per different size/class selection.

3. The torque value showed in above table is the valve torque at normal temperature. For customer's sizing actuator:

a. If medium temperature is -10℃'40℃, the output torque of actuator should be 1.5 times the valve torque;

b. If medium temperature is less than -10°C, the output torque of actuator should be 2 or 2.5 times the valve torque.

Floating Ball Valve Torque Value

| Size | Design Torque (N.m) | ||||

| (inch) | Class 150 | Class 300 | Class 600 | Class 900 | Class 1500 |

| 1/2 | 12 | 17 | 30 | 38 | 51 |

| 3/4 | 14 | 23 | 38 | 56 | 71 |

| 1 | 27 | 48 | 66 | 98 | 130 |

| 1-1/2 | 55 | 89 | 120 | 189 | 238 |

| 2 | 75 | 100 | 160 | 240 | 350 |

| 2-1/2 | 125 | 141 | 233 | 390 | 550 |

| 3 | 162 | 216 | 308 | 610 | 980 |

| 4 | 234 | 476 | 635 | — | — |

| 5 | 546 | 910 | — | — | --- |

| 6 | 804 | 1338 | 1944 | --- | --- |

| 8 | 1410 | 3100 | ・一 | 一 | 一 |

| 10 | 2600 | 5400 | — | — | --- |

Notes:

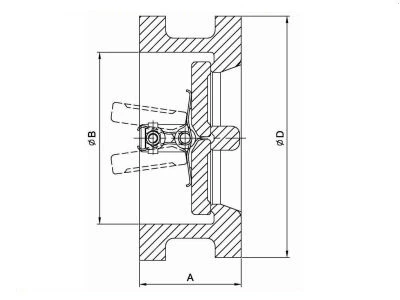

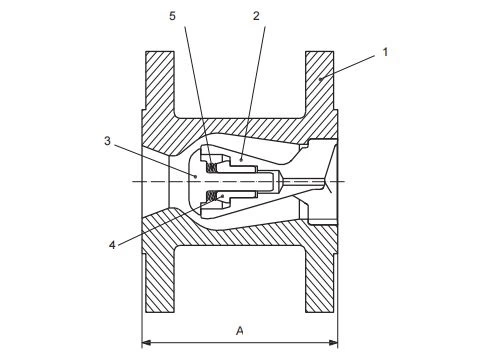

1. The above are for side entry split body floating ball valves.

2. All valves are in normal temperatu re, with PTFE seat for Class 150〜300 and Nylon seat for Class 600〜1500.

3. For cryogenic ball valve, torque wil be 2-2.5 times the a bove torque.

4. Torque shown in this table is to be used as a guide for actuator selection. A safety factor of 1.5 is recommended for actuator sizing.

5. Torque may be changed according to different medium a nd trim material.