ASTM A217 chemical composition, physical properties

ASTM A217 covers the chemical composition, physical properties of ASTM A217 WC1, WC5, WC6, WC9, WC11, C5, C12A and CA15.

ASTM A217/A217M specification covers martensitic stainless steel and alloy steel castings for valves, flanges, fittings, and other pressure-containing parts (Note 1) intended primarily for high-temperature and corrosive service (Note 2)

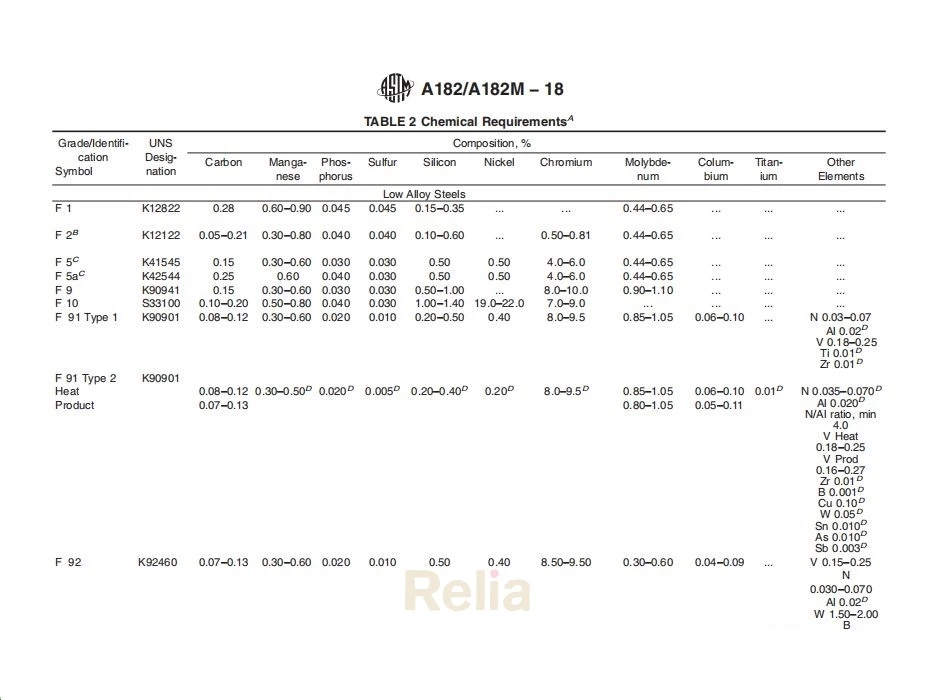

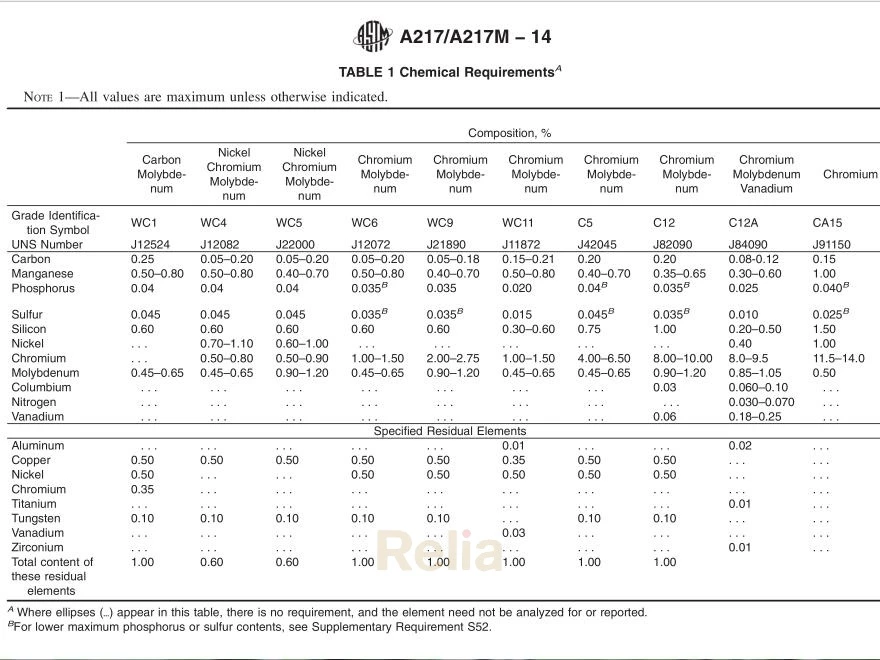

Chemical Composition

| Element,% | Grade UNS Number Type | |||||||||

| WC1 J12524 C-Mo | WC4 J12082 Ni-Cr-Mo | WC5 J22000 Ni-Cr-Mo | WC6 J12072 Cr-Mo | WC9 J21890 Cr-Mo | WC11 J11872 Cr-Mo | C5 J42045 Cr-Mo | C12 J82090 Cr-Mo | C12A J84090 Cr-Mo-V | CA15 J91150 Cr | |

| Carbon | 0.25 | 0.05-0.20 | 0.05-0.20 | 0.05-0.20 | 0.05-0.18 | 0.05-0.21 | 0.20 | 0.20 | 0.08-0.12 | 0.15 |

| Manganese | 0.50-0.80 | 0.50-0.80 | 0.40-0.70 | 0.50-0.80 | 0.40-0.70 | 0.50-0.80 | 0.40-0.70 | 0.35-0.65 | 0.30-0.60 | 1.00 |

| Phosphorus | 0.04 | 0.04 | 0.04 | 0.035 | 0.035 | 0.020 | 0.04 | 0.035 | 0.025 | 0.040 |

| Sulfur | 0.045 | 0.045 | 0.045 | 0.035 | 0.035 | 0.015 | 0.045 | 0.035 | 0.010 | 0.025 |

| Silicon | 0.60 | 0.60 | 0.60 | 0.60 | 0.60 | 0.30-0.60 | 0.75 | 1.00 | 0.20-0.50 | 1.50 |

| Nickel | ... | 0.70-1.10 | 0.60-1.00 | ... | ... | ... | ... | ... | 0.40 | 1.00 |

| Chromium | ... | 0.50-0.80 | 0.50-0.90 | 1.0-1.50 | 2.00-2.75 | 1.00-1.50 | 4.00-6.50 | 8.00-10.00 | 8.0-9.5 | 11.5-14.0 |

| Molybdenum | 0.45-0.65 | 0.45-0.65 | 0.90-1.20 | 0.45-0.65 | 0.90-1.20 | 0.45-0.65 | 0.45-0.65 | 0.90-1.20 | 0.85-1.05 | 0.50 |

| Columbium | ... | ... | ... | ... | ... | ... | ... | 0.03 | 0.060-0.10 | ... |

| Nitrogen | ... | ... | ... | ... | ... | ... | ... | ... | 0.030-0.070 | ... |

| Vanadium | ... | ... | ... | ... | ... | ... | ... | 0.06 | 0.18-0.25 | ... |

| Specified Residual Elements | ||||||||||

| Aluminum | ... | ... | ... | ... | ... | 0.01 | ... | ... | 0.02 | ... |

| Copper | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.35 | 0.50 | 0.50 | ... | ... |

| Nickel | 0.50 | ... | ... | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | ... | ... |

| Chromium | 0.35 | ... | ... | ... | ... | ... | ... | ... | ... | ... |

| Titanium | ... | ... | ... | ... | ... | ... | ... | ... | 0.01 | ... |

| Tungsten | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | ... | 0.1 | 0.1 | 0.1 | 0.1 |

| Vanadium | ... | ... | ... | ... | ... | 0.03 | ... | ... | ... | ... |

| Zirconium | ... | ... | ... | ... | ... | ... | ... | ... | 0.01 | ... |

| Total Content of Residual Elements | 1.0 | 0.60 | 0.60 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | ... | ... |

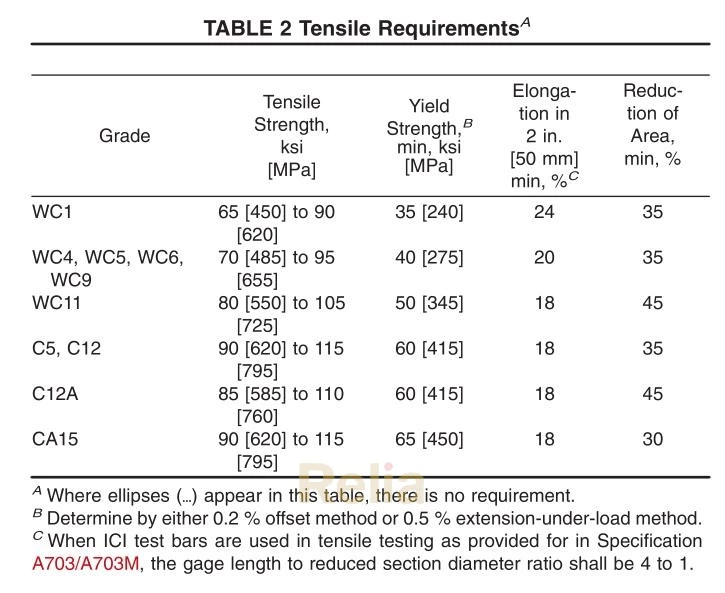

Physical Properties

| Grade | Tensile Strength, ksi [MPa] | Yield Strength, ksi [MPa] B | Elonga- tion in 2 in. [50 mm], % | Reduc- tion of Area, % |

| WC1 | 65–90 [450–620] | 35 [240] | 24 | 35 |

| WC4, WC5, WC6, WC9 | 70–95 [485–655] | 40 [275] | 20 | 35 |

| WC11 | 80–105 [550–725] | 50 [345] | 18 | 45 |

| C5, C12 | 90–115 [620–795] | 60 [415] | 18 | 35 |

| C12A | 85–110 [585–760] | 60 [415] | 18 | 45 |

| CA15 | 90–115 [620–795] | 65 [450] | 18 | 30 |

Note A - All values are minimums unless a range is provided.

Note B - Determine by either 0.2 % offset method or 0.5 % extension-under-load method.

Note C - When ICI test bars are used in tensile testing as provided for in Specification A703/A703M, the gage length to reduced section diameter ratio shall be 4 to 1